-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Write your own review

Reviews

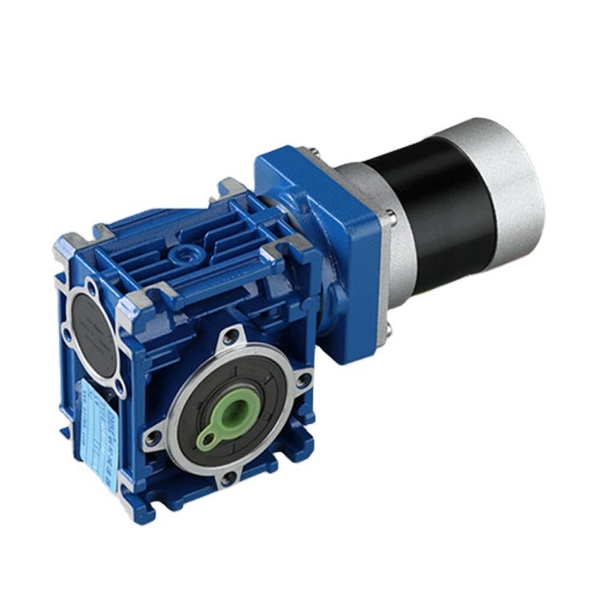

High efficiency capacity, low noise

Surprise after purchase! This 50W BLDC worm gear motor runs exceptionally stable at 12V/24V with low power consumption and minimal noise. It enhances the performance of the equipment and is definitely worth every penny.

Zenith

|

11/24/2023 12:14 AM

Was this review helpful?

(0/0)

Love this worm gear motor

I love the compact size of 50W worm gear motor. It seems to be of good machined quality and materials. I hope it will last a long time.

Glanna

|

3/23/2023 2:11 AM

Was this review helpful?

(0/0)

Powerful motors

I bought three 50W worm gear motors. It's easy for mounting and they work quietly. Seems to be of good machined quality and materials. I love the compact size. I would recommend it.

Gibson

|

10/24/2022 7:48 PM

Was this review helpful?

(0/0)